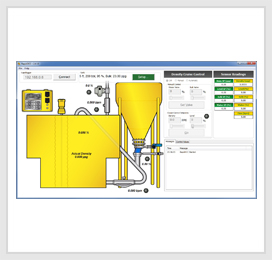

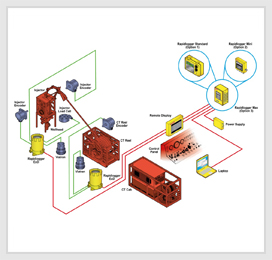

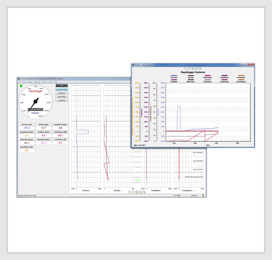

Rapidlogger for cementing & pumping is a self-contained, state-of-the-art system for data monitoring and recording on cementing and pumping units. The Rapidlogger can record, monitor, and display pump-rate, volume, pressure, temperature, wellhead pressure, and other rig parameters. One system can monitor and record from both single or double pump units. CE marked and ATEX Zone II Certified versions also available.

The Rapidlogger System for Drilling Rigs is a compact standalone and cost-effective system for oilfield data acquisition and control. A single unit can be used for pump monitoring, cementing, mud, coiled tubing and slickline units. Additionally multiple Rapidlogger systems can be connected together over a digital bus for creating complex rig control solutions.

Rapidlogger for coiled tubing is a customized, state-of-the-art system for monitoring and recording CT jobs. The Rapidlogger can record, monitor, and display depth, tension, circulating pressure, wellhead pressure, pump-rate, volume, and other parameters. One system can monitor and record from both single or double pump units. Free Coiled Tubing force, stuck point analysis, and design overlay software modules are included with each system.

Rapidlogger for Slickline is a self-contained, state-of-the-art system for data monitoring and recording on slickline, coiled tubing and wireline and perforating units. The Rapidlogger can record, monitor, display and report depth, speed, tension, wellhead pressure, pump-rate, pump-volumes, wellhead pressure and parameters. CE marked and ATEX Zone II certified versions also available.

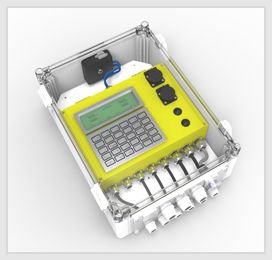

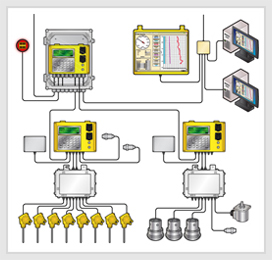

Rapidlogger Data Interface is a rugged data interface with serial and Ethernet capabilities. The Data Interface is suitable for use on earth moving equipment, crane trucks, mud pumps, and anywhere exceptional ruggedness is needed. The Data Interface has an eight line by twenty character display and a numeric keypad. CE marked and ATEX Zone II certified versions also available.

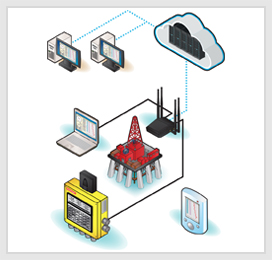

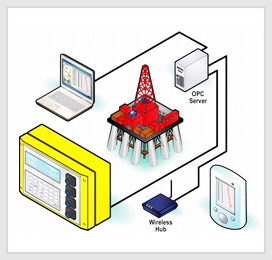

The Rapidlogger SCADA Gateway allows Rapidlogger and other third party hardware and software systems to communicate with Modbus and OPC Servers over Ethernet. All that is needed is a system capable of transmitting or accepting data as ASCII streams, Modbus, WITS or OPC channels.