Applications

The Rapidlogger Mini is a compact and cost-effective system for job monitoring and recording on cementing units. It is suitable for use on all type of single pump pumping units.

The system is simple to use and an equipment operator can use the system without any training. Job data can be recorded on removable and upgradeable MMC/SD/USB flash memory cards.

Highlights

The Rapidlogger Mini can be used in many different applications. When used in the cement or acid pump mode the system measures, displays and records, the pump pressure, rates, volumes, density and any other parameters that the user may choose. It can also be setup to trip the pump if the pressure exceeds a preset high limit.

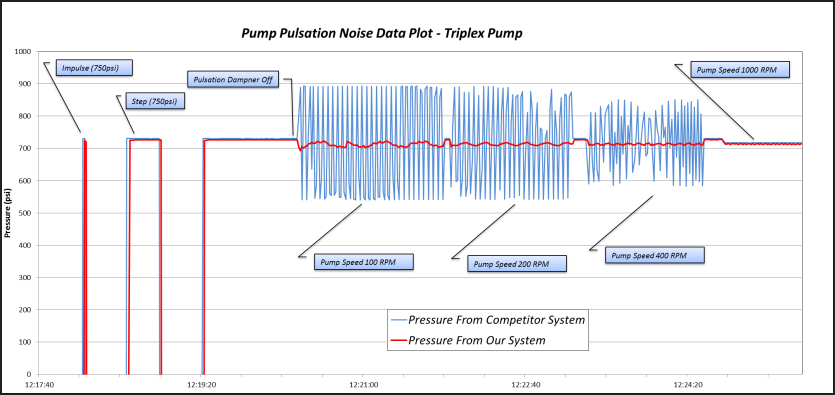

One of the new features of the Rapidlogger is its ability to eliminate pump pulsation noise from the recorded data. The system accomplishes this by means of high-speed data acquisition and digital signal processing techniques.

The Rapidlogger does not need a PC for operation. However, if needed it can transmit data to a PC or server in real time. The large internal memory can record many months of job data for future retrieval. The package is very compact and suitable for mounting in the control cabs of wireline, slickline and coiled tubing trucks.

Software

RapidVu is the software for graphing and preparing job reports and runs on a PC computer. It can display real-time graphs and easily prepare job reports for the operator.

Specifications

| Operating Temperature: | -40C to 70C |

| Operating Enviornment: | NEMA 4X |

| Analog Inputs: | 4 16 bit |

| Frequency / Depth Inputs: | 4 max |

| Display: | LCD w/ Backlight |

| Computer Interface: | Serial, Ethernet, WiFi |

| Power: | 12/24 DC, 110/240AC |

| Job Memory: | 16 GB |