For slickline and wireline operations depth and line tension are the most important measured parameters. The depth for a slickline operation is usually measured by means of a friction wheel or a pinch wheel that the slickline is wrapped around. As the slickline is paid out in to the well or as it is pulled back in on the winch drum, the wheel rotates.

The pinch wheel is connected to a depth encoder and every rotation of the wheel is measured by the encoders. In order to calculate the measured depth from the pulses counted by the encoder the following are required: The circumference of the pinch wheel, the thickness of the slickline and the number of pulses per rotation of the encoder. The Rapidlogger data acquisition system can calculate an accurate slickline depth from these parameters. The value can be calculated, displayed and recorded.

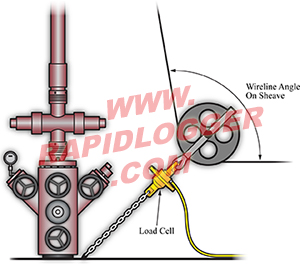

Line tension for a slickline operation is measured by means of a tension link or load cell. The load cell is installed in the shackles that hold the lower sheave wheel on the slickline.

The line tension in the slickline tries to pull the sheave away from the load cell and the loadcell measures the amount of this pull. In order to calculate the line tension from the load cell signal the following need to be known: The angle of the slickline as it goes over the sheave wheel, the full scale sensor reading of the load cell. With these two parameters know a modern data acquisition system such as the Rapidlogger can display and record the slickline tension automatically. The Rapidlogger data acquisition has a built in mode for efficiently setting up and recording oilfield cementing jobs.